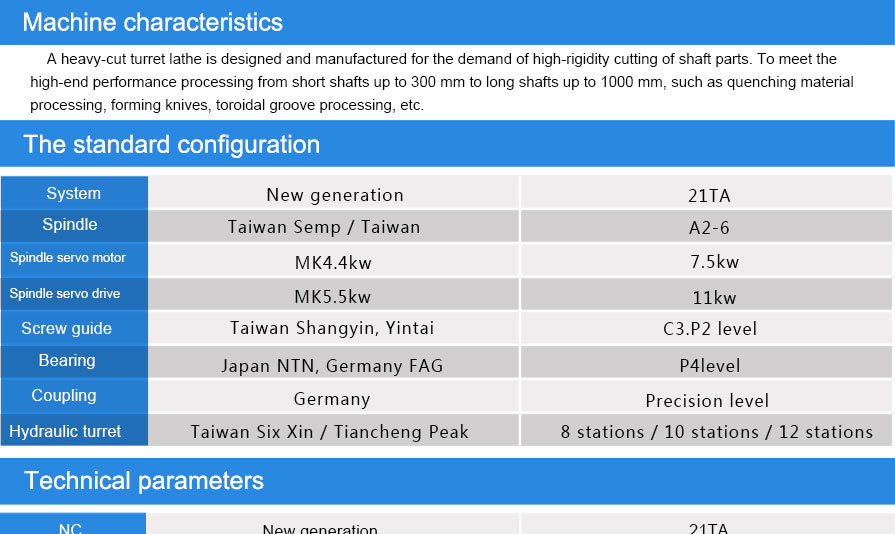

Screw brand: using Taiwan's silver or Yintai precision ball screw

Oil cooler: using Rico oil cooler

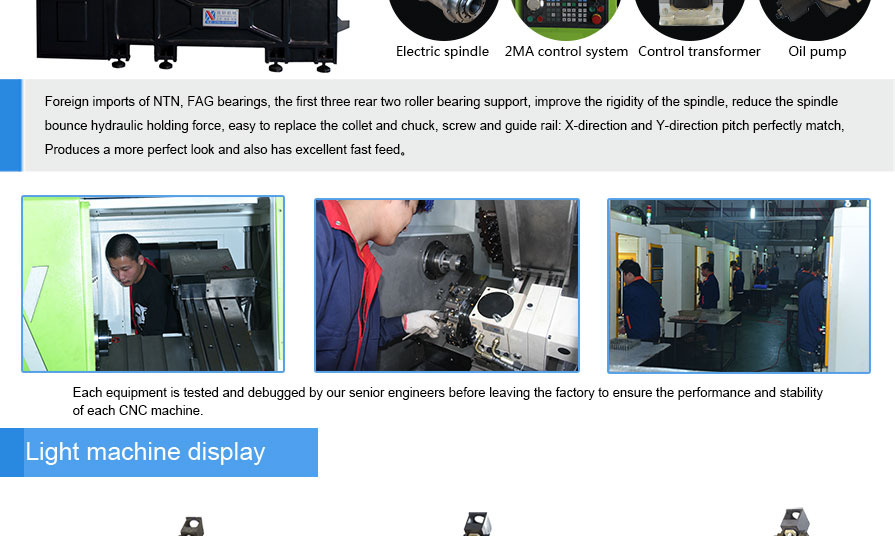

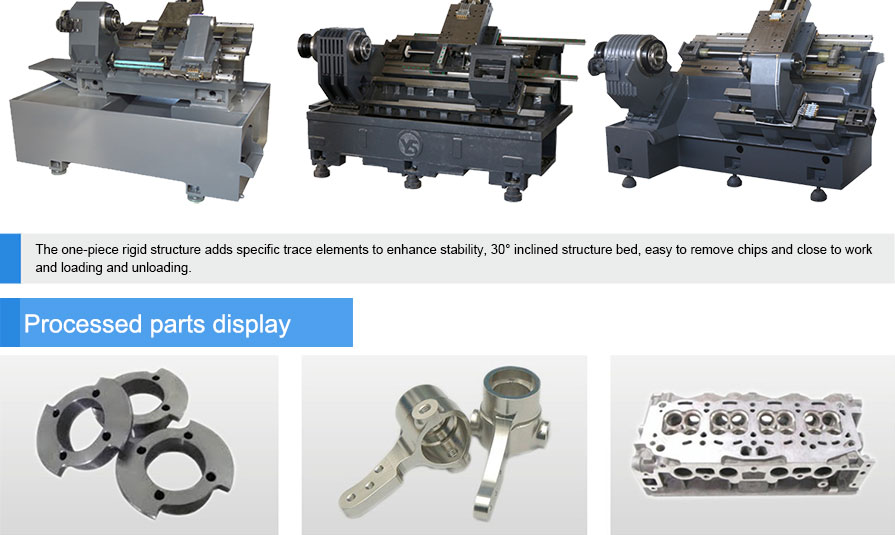

Machine features:The overall layout of the rowing machine series is compact, with a small footprint and independent spindle unit. The temperature is low...

Return ListOil cooler: using Rico oil cooler

Standard configuration details

1 KND1000T bus type system 6 Automatic lubrication system

2 KND absolute servo motor 7 Chip fluid system5 USB and Ethernet interface 10 Toolbox and random technical parts

Adopting a line-type control system, system features

1. Wide vision high brightness LCD screen

2. Four-axis complete servo axis hand wheel special connector

3. The second panel of the new generation of technology film metal shrapnel milling machine

4. Metal shrapnel button and anti-oil and corrosion resistance

5. Independent six INPUT / OUTPUT point supply with self-planning

6. New generation standard keyboard design

Adopting Taiwan silver linear guide

The linear slide rail is a four-row single-arc-shaped contact linear slide rail, and integrates the heavy-duty precision linear slide rail with optimized structural design. Compared with other linear slide rails, it improves the load and rigidity, and has four directions. The load characteristics and self-aligning function can absorb the assembly error of the mounting surface and obtain high-precision appeal. The concept of high speed, high load, high rigidity and high precision has become the trend of future industrial products development in the world.